Maple

Powerful math software that is easy to use

• Maple for Academic • Maple for Students • Maple Learn • Maple Calculator App • Maple for Industry and Government • Maple Flow • Maple for Individuals

Pipeline designers use math tools to:

Maple Flow provides a freeform, paper-like, calculation environment.

Learn more about Maple Flow.

Mathcad is a registered trademark of PTC Inc. or its subsidiaries in the U.S. and in other countries. MATLAB is a registered trademark of The MathWorks, Inc.

Design engineers need to ensure code compliance with readable, auditable calculation reports. You can use Maple Flow to implement ASME B31 pipe codes for pressure piping, as well as their international equivalents (such as AS4041, BS 010230 and DNVGL-ST-F101).

Design engineers use Maple Flow to determine head and flowrates in pipes and pipe networks. These calculations often need strong iterative solvers. You can collect these equations together in an unstructured form, and solve them with Maple Flows math functions. You can also implement standard semi-theoretical equations for predicting gas flow through long pipelines, such as the Weymouth or IGT equations.

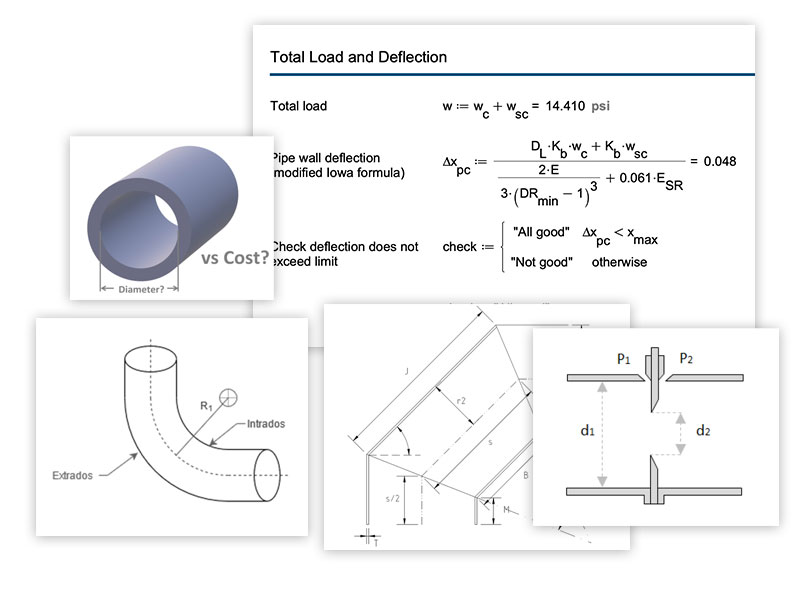

Economic planning influences engineering design. Maple Flow can be used to determine economic pipe sizes and operating conditions

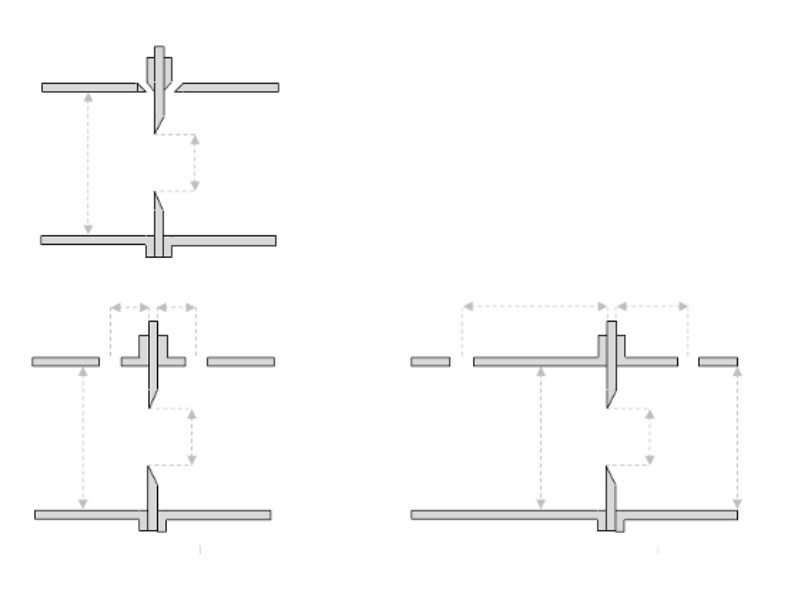

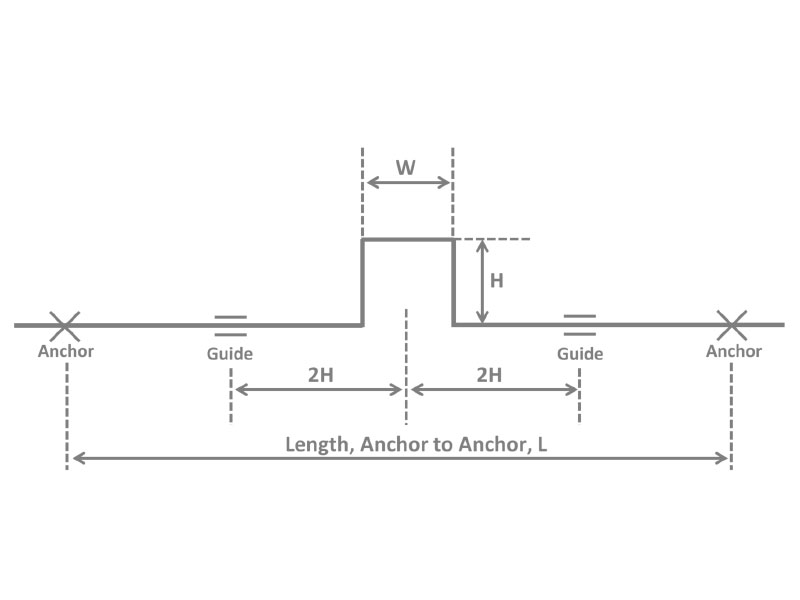

Engineers use Maple Flow to size valves and orifices or to calculate the flow through orifice meters.

Maple Flow offers a full, computable database of transport and thermodynamic properties for liquids and gases. This database can be linked to your calculations, so that properties are maintained when two intendent states (such as temperature and pressure, or temperature and entropy) change.

Maple Flow can be used to implement the equations that describe the deflection of rigid or flexible pipes, buried in soil. The modified Iowa formula is the accepted method of calculating the vertical deflection of buried flexible pipes. The strength of rigid pipes (such as those made of concrete or steel) is determined by Marston theory.

Both approaches can be implemented with Maple Flow, providing auditable, readable calculation reports.