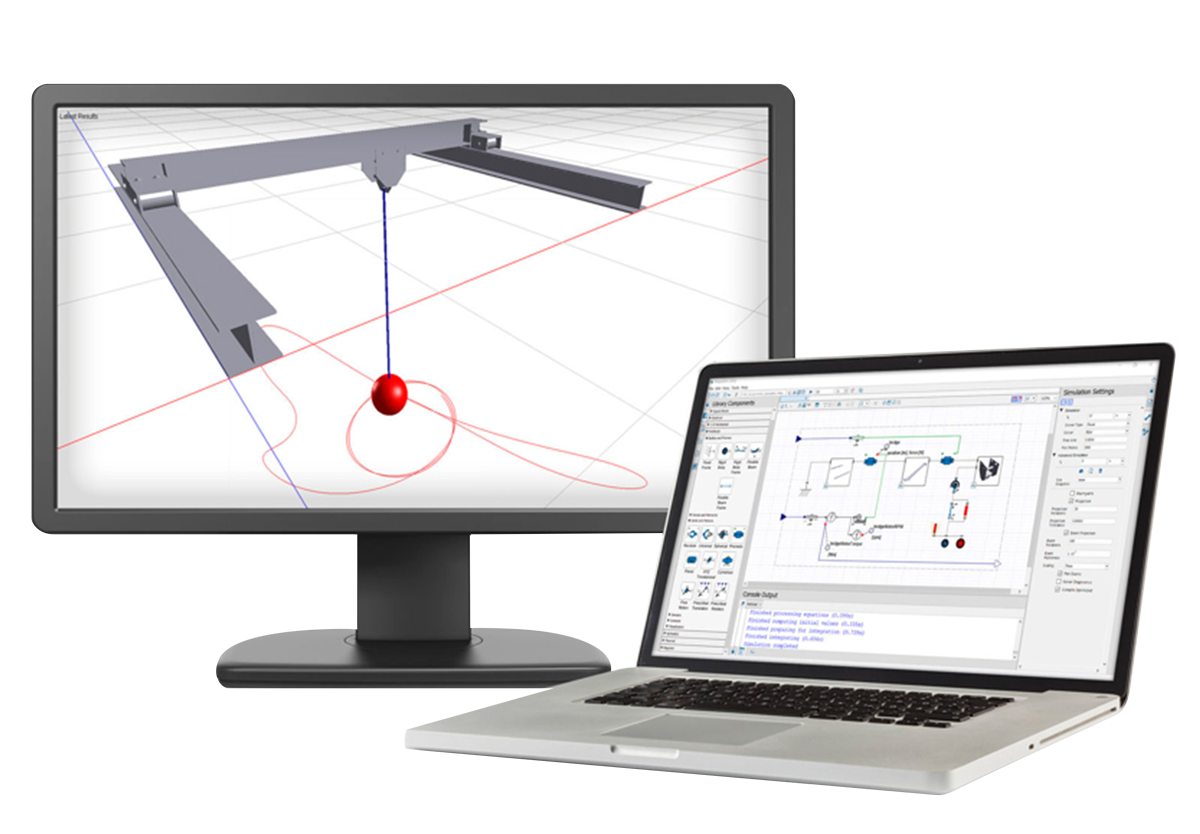

MapleSim is a very efficient way to make detailed models of machine components along with the torque and other forces that affect dimensioning

- Dr. Kurt Zehetleitner, B&R Industrial Automation

Maple

Powerful math software that is easy to use

• Maple for Academic • Maple for Students • Maple Learn • Maple Calculator App • Maple for Industry and Government • Maple Flow • Maple for Individuals

B&R MapleSim Connector

B&R MapleSim Connector